Hi,

Although all the sensors are wired in the PLC, I would like to know if the PLC ethernet can process I/O without the internet wireless

Hi,

Although all the sensors are wired in the PLC, I would like to know if the PLC ethernet can process I/O without the internet wireless

A PLC does not need any internet connection to process I/O.

Thanks. So, the only way to have I/O problems is if the network, Bluept, mac address, subnet… are not well configured.

I am extremely confused by your question. There are a number of issues that can lead to “I/O problems” outside what you’ve mentioned.

Ok, I just emphasized some of them. Thanks Sr.

Hi Vlad,

I have another question about the HMI logic. I do not have the Factory Talk View to see the HMI associated with the program that I am working on as well as I do not see any “HMI logic file” created in Main Program, but I do see some HMI inputs rungs created in different files, such as boom, engine, left ext mill, water pump, suspension … . Is the program correct? Do you need to create a file or you can use any HMI input rung created in the other files and do the the interface with the Factory Talk View Status.

Also, it would be nice to know about the PLC memory. I saw that the memory card is placed in the HMI screen, is there any other way to insert memory with the program logic in the PLC system? Because probably after understand the program that I am working on we will make some changes and I would like to test it on the machines, but I would not like to mess up with the current program, so what would be the best way to do that?Also, is there anyway of the current program keep in the memory after switch the program option in case I want to reuse it , or once you update the program the previously program that was running before will be erased from the memory? Using a USB and change the settings to read the modified program, or install the second updated program in the same memory card and just switch from there? Once changed the program the current program will be available on system in case I want to use it again or as soon as you change it will be erased from the memory? I am little concern to mess up because I do not know if the program that I am working on is the same installed in the plc system. So I have to be careful about that. We are using the Compact Logix 5563.

Thanks in advance!

Best Regards,

Phelipe

“I have another question about the HMI logic. I do not have the Factory Talk View to see the HMI associated with the program that I am working on as well as I do not see any “HMI logic file” created in Main Program, but I do see some HMI inputs rungs created in different files, such as boom, engine, left ext mill, water pump, suspension … . Is the program correct?”

“Do you need to create a file or you can use any HMI input rung created in the other files and do the the interface with the Factory Talk View Status.”

“Also, it would be nice to know about the PLC memory. I saw that the memory card is placed in the HMI screen, is there any other way to insert memory with the program logic in the PLC system? Because probably after understand the program that I am working on we will make some changes and I would like to test it on the machines, but I would not like to mess up with the current program, so what would be the best way to do that?”

You can store programs in memory cards, but they overwrite what is in the PLC memory; you can’t run a program directly from the memory card the way you’re describing. This is often used to backup a program in case the PLC memory fails.

The best way to do what you’re describing would be to create a backup of the current program, work with the program you want to test and to download the backup back to the PLC once you’re done.

“Also, is there anyway of the current program keep in the memory after switch the program option in case I want to reuse it , or once you update the program the previously program that was running before will be erased from the memory? Using a USB and change the settings to read the modified program, or install the second updated program in the same memory card and just switch from there? Once changed the program the current program will be available on system in case I want to use it again or as soon as you change it will be erased from the memory?”

No, there’s no way to keep two programs in memory, as far as I know.

As I mentioned above, you should create a backup of the current program before proceeding.

Another tip I’d give would be to incorporate elements of the program you want to test into the current one. In other words, you probably have a routine you want to test; you can import that routine into the current program and delete it when you’re done.

I did not see the hardware part yet because the machines are on the site. Do you know where the memory card position from Logix 5563 is?

You said : "you can’t run a program directly from the memory card the way you’re describing. This is often used to backup a program in case the PLC memory fails. Sorry, I did not understand clearly, because in the way that you said seems like the PLC has two memory options by saying if the memory fails( Which memory? Could you be more specific?) the memory card can be as back up. I though that the memory card was the only “memory” from PLC, but seems like the PLC has another one. Sorry for insisting, it is not clear for me yet.

Hi Phelipe,

“I did not see the hardware part yet because the machines are on the site. Do you know where the memory card position from Logix 5563 is?”

"You said : “you can’t run a program directly from the memory card the way you’re describing. This is often used to backup a program in case the PLC memory fails. Sorry, I did not understand clearly, because in the way that you said seems like the PLC has two memory options by saying if the memory fails( Which memory? Could you be more specific?) the memory card can be as back up. I though that the memory card was the only “memory” from PLC, but seems like the PLC has another one. Sorry for insisting, it is not clear for me yet.”

Thanks Sr, I understood now.

Hi,

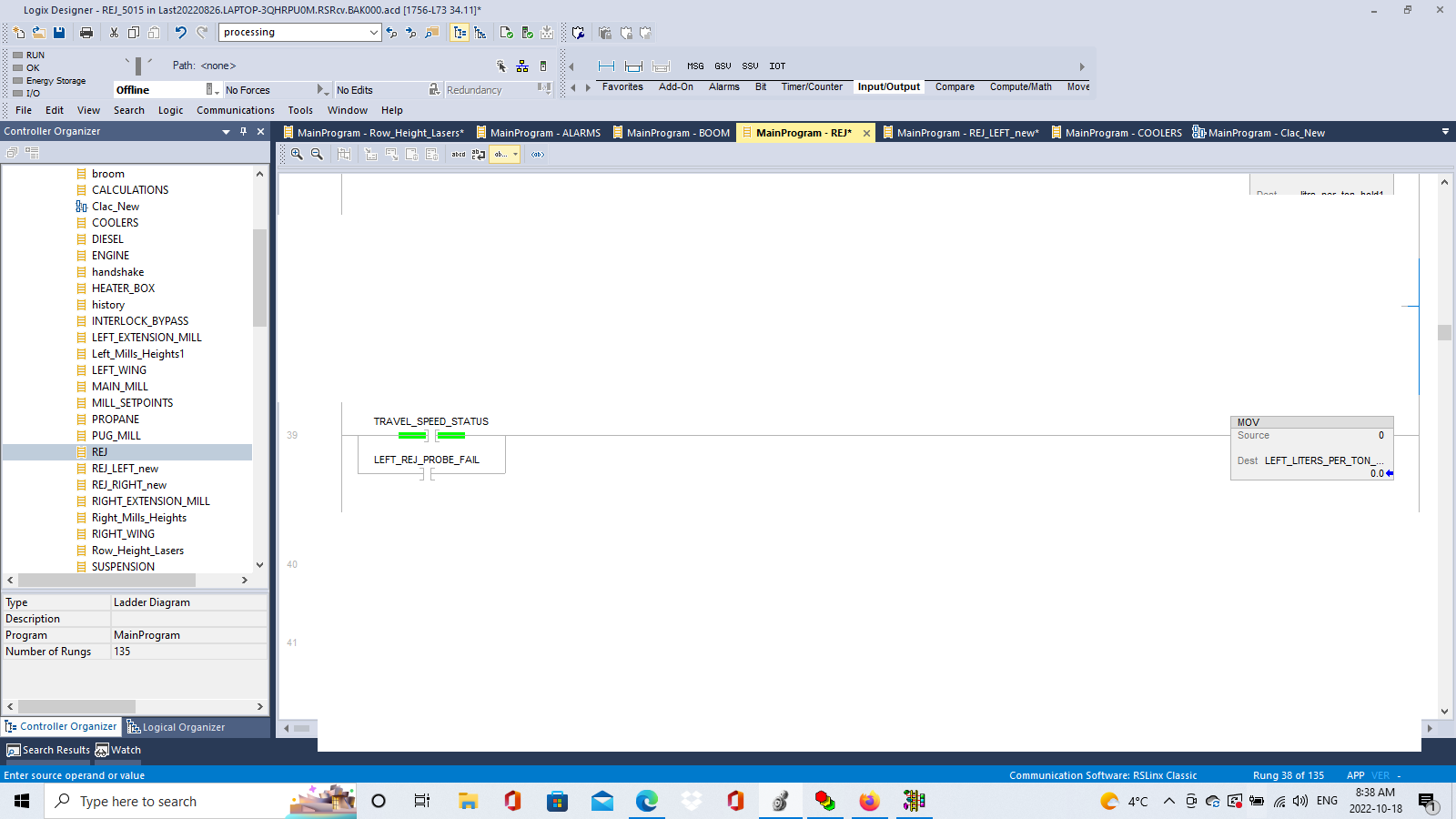

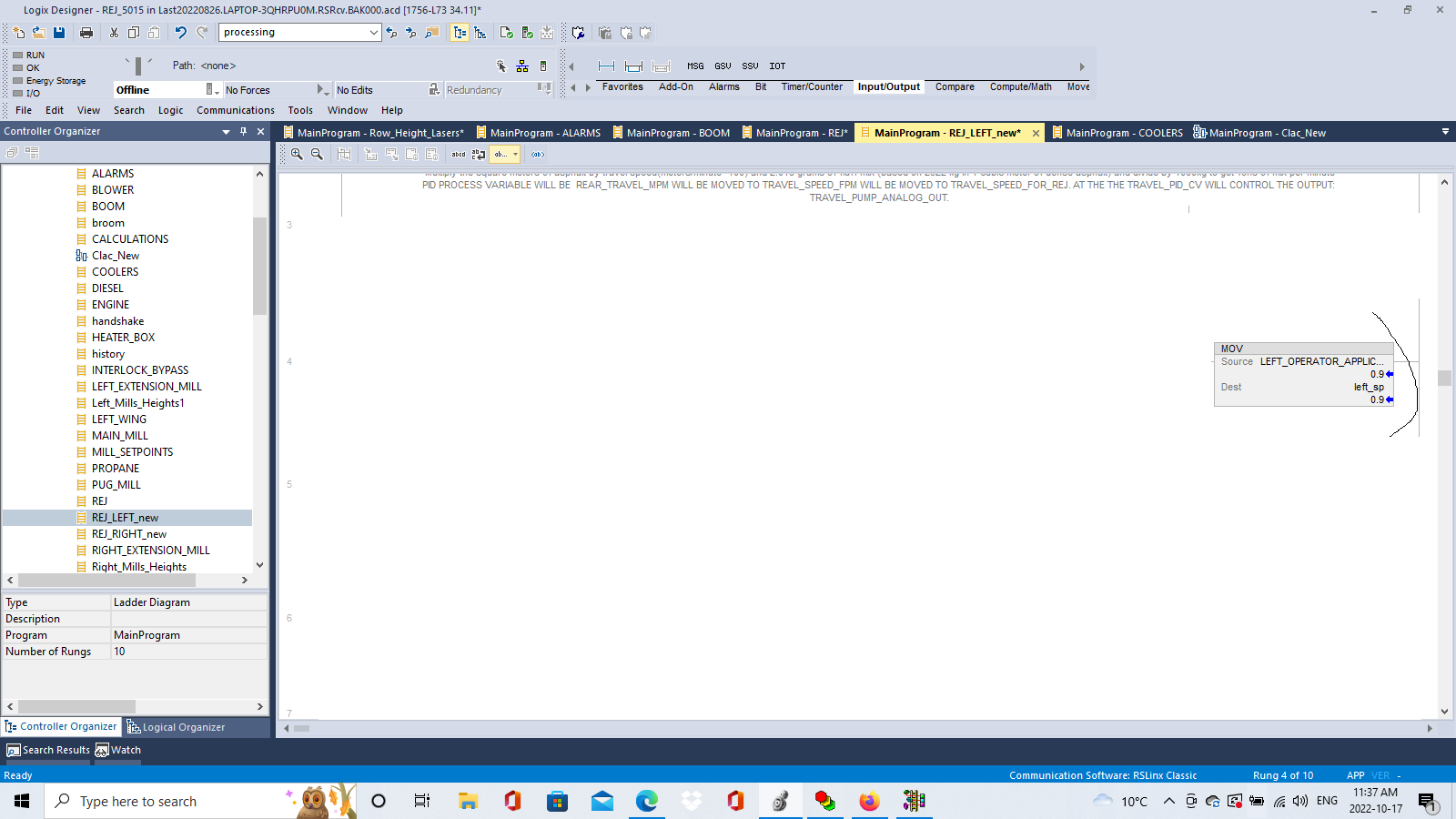

I have another question about the MOV. There are two blue sign besides the numbers. How do I know if it it is fixed number or not. Please, see the picture below:

Another question, all the alarms have to be on the HMI or the reason why it is just for the operator have access remotely, because on the program that I am working have many logical layers , but I don’t not remember if I saw on the HMI screen. these alarms.

I’m not sure I follow the MOV question. What do you mean by “fixed number”? Both are registers; they can be changed by PLC code and are therefore not fixed.

All alarms on the PLC don’t have to be on the HMI.

Hi,

Thanks Sr, I just was wondering about the " preset- fixed numbers". Sorry, I should have sent you both pictures. For instance, the move source: 0 has no blue sign beside and I was thinking that could be a fixed value that could be moved to other presets. Thanks in advance!